You’ve just finished a dryer cycle, opened the door, and reached for your clothes—only to find them still damp and cold. Sound familiar? A dryer that runs but doesn’t heat is one of the most frustrating appliance problems San Francisco homeowners face, especially in apartments where laundromat trips aren’t convenient.

The good news? Many dryer heating issues have simple solutions you can tackle yourself in under an hour, while others require professional expertise to ensure safety and proper repairs. Whether you’re dealing with a gas dryer in your Pacific Heights Victorian or an electric model in your Sunset District apartment, this comprehensive guide will help you diagnose the problem, understand your options, and get your laundry routine back on track. Most issues can be identified within 30 minutes, and many cost less than $50 to fix.

Why Your Dryer Isn’t Heating: The 8 Most Common Causes

Before you grab your toolbox or call a repair technician, it helps to understand what’s actually happening inside your dryer. Whether you have a gas or electric model, the heating mechanism involves multiple components working together—and when one fails, your clothes stay wet. Here are the most common culprits, ranked by frequency based on thousands of repair calls across San Francisco.

Cause #1: Clogged Dryer Vent (35-40% of Cases)

The number one reason dryers stop heating is restricted airflow from lint buildup in the vent system. When hot air can’t escape properly, your dryer overheats and triggers safety mechanisms that shut off the heating element or gas burner to prevent fires. This isn’t just a performance issue—it’s a serious fire hazard. According to the U.S. Fire Administration, dryers cause approximately 2,900 home fires annually, with failure to clean being the leading factor.

In San Francisco apartments, this problem is particularly common because vent systems often run through walls and multiple floors, creating longer duct runs where lint can accumulate. Even if your lint screen looks clean, buildup deep in the vent system can completely block airflow, causing your dryer to overheat and shut down its heating function.

Cause #2: Blown Thermal Fuse (25% of Cases)

Think of the thermal fuse as your dryer’s emergency stop button. This one-time safety device blows when temperatures exceed safe limits—usually around 185-220°F depending on the model—permanently cutting power to the heating system. Once it blows, the dryer will run normally, the drum will spin, and the timer will count down, but no heat will be produced until you replace the fuse.

The thermal fuse is designed to fail when your dryer overheats, which happens most often due to clogged vents. It’s a small component, typically about the size of your thumb, that costs only $10-30. However, simply replacing the fuse without addressing the underlying cause—usually inadequate airflow—means the new fuse will blow again within days or even hours.

Cause #3: Tripped Circuit Breaker (Electric Dryers – 15% of Cases)

Here’s a tricky one that confuses many homeowners: electric dryers need 240 volts from TWO circuit breakers to operate properly. If just one breaker trips, your dryer gets 120 volts—enough to spin the drum, light up the display, and make you think everything is working fine—but not enough to power the heating element.

This partial power situation is the single most misdiagnosed dryer problem. You’ll see the dryer running, hear the drum tumbling, and assume it has full power. Meanwhile, your clothes stay damp because the heating element requires the full 240 volts to function. In older San Francisco buildings with Federal Pacific or Zinsco electrical panels, breakers are particularly prone to tripping, sometimes without moving to the obvious “off” position.

Cause #4: Failed Heating Element (Electric Dryers – 10% of Cases)

The heating element in electric dryers is a metal coil that glows red-hot when electricity flows through it, similar to an oven element or space heater. These coils are made of nichrome wire wound tightly inside a metal housing. Over time, repeated heating and cooling cycles create thermal stress that can cause the metal to weaken and eventually break.

When a heating element fails, you’ll typically see a visible break in the coil, or the element will show no continuity when tested with a multimeter. Sometimes the break is obvious—a clear gap in the wire. Other times, it’s microscopic but still prevents electrical current from flowing through. The element might also short to the metal housing if the coil breaks loose and touches the casing, which will trip your circuit breaker immediately when the heating cycle starts.

Cause #5: Bad Igniter (Gas Dryers – 10% of Cases)

Gas dryers use an igniter that must glow bright orange or red-hot to perform two critical functions: heat the gas valve to the point where it opens, and ignite the gas when it flows. The igniter is typically made of silicon carbide or a similar ceramic material that becomes extremely hot when electricity passes through it—reaching temperatures around 2500°F.

After years of heating and cooling cycles, igniters can crack, weaken, or fail completely. Even hairline cracks that are barely visible can prevent the igniter from reaching the temperature needed to open the gas valve. This is the most common gas dryer heating failure and typically occurs after 3-5 years of regular use. If your igniter doesn’t glow at all, or glows weakly (dim orange instead of bright orange-red), it needs replacement.

Cause #6: Faulty Gas Valve Coils (Gas Dryers – 5% of Cases)

Even if the igniter glows perfectly, the gas valve solenoid coils must work properly to actually open the valve and allow gas to flow. These electromagnetic coils create a magnetic field when energized, pulling open the valve mechanism. Most gas dryers have two or three coils, and both must function for gas to flow.

When gas valve coils fail, you’ll see the igniter glow for 30-90 seconds (or even continuously), but no flame will appear because gas isn’t reaching the burner. The igniter continues glowing because the control system is waiting for the flame sensor to detect heat, which never happens. This situation requires professional diagnosis and repair, as gas valve work should only be performed by licensed technicians.

Cause #7: Closed Gas Supply Valve (User Error – 5% of Cases)

Sometimes the simplest explanation is correct. If someone accidentally turned off the gas supply valve during cleaning, moving furniture, or any work behind the dryer, your appliance won’t heat no matter how well it’s maintained. The gas shutoff valve is typically located on the supply line connecting your home’s gas system to the dryer.

To check if your gas valve is open, look at the handle position. When the handle is parallel to the gas pipe, the valve is open and gas can flow. When the handle is perpendicular (forming a T or cross with the pipe), the valve is closed. Simply turn the handle until it’s parallel with the pipe to restore gas flow. This simple fix resolves about 5% of gas dryer heating problems and takes literally 10 seconds.

Cause #8: Incorrect Dryer Settings (User Error – 5% of Cases)

Before disassembling anything or calling a technician, double-check your dryer settings. Most dryers have “Air Fluff,” “Air Dry,” or “No Heat” cycles specifically designed to tumble clothes without heat—useful for fluffing pillows or freshening clothes. If one of these settings was accidentally selected, your dryer is working exactly as designed.

Also verify the timer hasn’t been accidentally adjusted to a very short cycle. Some electronic control models have sensitive touch controls that can be bumped, while older mechanical timer models have dials that can be rotated easily. Take 30 seconds to ensure you’ve selected a normal heat-producing cycle like “Regular Dry,” “Permanent Press,” or “Heavy Duty” before assuming a mechanical problem.

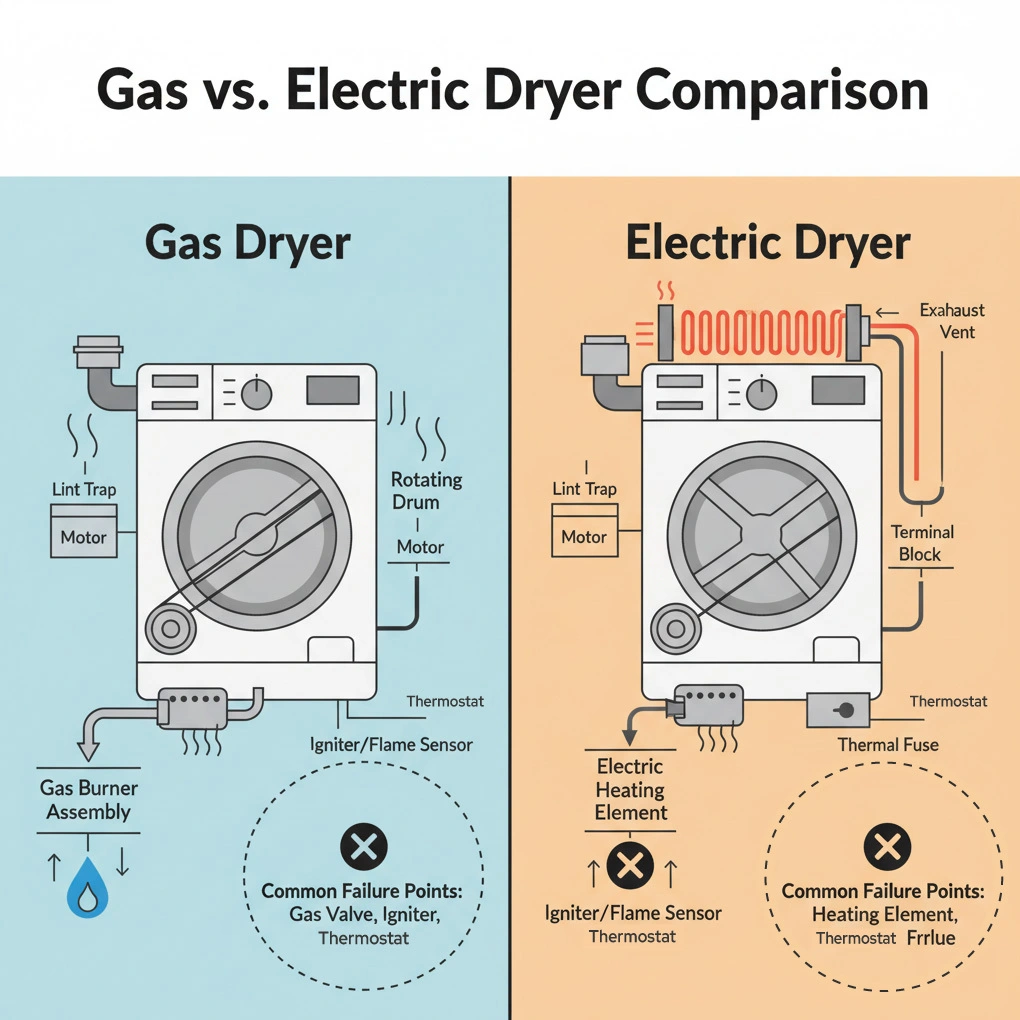

Gas vs. Electric Dryers: Understanding Your Heating System

The troubleshooting path you’ll take depends entirely on your dryer type. Gas and electric dryers heat clothes using completely different mechanisms, with distinct components that can fail. Understanding these differences is crucial for accurate diagnosis and knowing when DIY is appropriate versus when professional help is required.

How to Identify Your Dryer Type

Many homeowners aren’t sure which type of dryer they have, especially if they moved into a home with appliances already installed. Here’s how to identify yours:

Electric Dryers Have:

- Heavy-duty electrical outlet with 3 or 4 large prongs (240-volt connection)

- No gas line connection visible

- Model number often contains “E” designation

- Slightly higher operating costs in most California areas

Gas Dryers Have:

- Standard 120-volt electrical outlet (3 regular prongs)

- Gas supply line connected to the back (usually yellow flexible tube or black pipe)

- Model number often contains “G” designation

- Lower energy costs but higher initial purchase price

Quick Visual Test: Look behind your dryer. If you see a gas line, you have a gas dryer. If there’s only a thick electrical cord with a large outlet, it’s electric. The electrical outlet for electric dryers is distinctly different—much larger and heavier duty than standard household outlets.

How Electric Dryers Generate Heat

Electric dryers are simpler in design but require substantial electrical power. They pull 240 volts of electricity through a heating element—a tightly coiled metal wire inside a metal housing. As electricity flows through this high-resistance coil, it heats up to approximately 400-500°F, glowing red like a stove burner.

A blower fan pulls room-temperature air across the glowing heating element, heating it before circulating the warm air through the tumbling drum. As the heated air passes through your damp clothes, it absorbs moisture, carrying it out through the exhaust vent. Thermostats constantly monitor the temperature, cycling the heating element on and off to maintain consistent heat levels and prevent overheating.

The heating element typically draws 15-30 amps of current, which is why electric dryers require dedicated 240-volt circuits with double circuit breakers. This high power requirement is also why a single tripped breaker can cause the confusing situation of a running dryer that produces no heat.

How Gas Dryers Generate Heat

Gas dryers use a small amount of electricity—only 120 volts—to run the motor, controls, and ignition system, but they generate heat by burning natural gas or propane. The heating process is more complex but more energy-efficient than electric models.

When you start a drying cycle, the control system sends power to the igniter, which begins glowing bright orange. After 30-90 seconds of heating, the igniter reaches approximately 2500°F. This intense heat causes the gas valve’s bimetal actuator to expand, opening the valve and allowing gas to flow to the burner assembly. The glowing igniter immediately lights the gas, creating a blue flame that heats the air.

Throughout the drying cycle, a flame sensor monitors combustion. If the flame goes out unexpectedly—indicating a potentially dangerous situation—the sensor signals the control board to shut off the gas valve immediately. The burner cycles on and off as needed to maintain the proper temperature, just like a gas furnace. Combustion byproducts (primarily water vapor and carbon dioxide) exhaust through the same vent system that removes moisture from your clothes.

Why This Matters for Troubleshooting

Electric dryers have fewer moving parts in the heating system—essentially just the heating element and thermostats—but they require proper voltage to function. A partial power issue will leave you with a non-heating dryer. Gas dryers have a more complex ignition sequence with multiple potential failure points (igniter, gas valve coils, flame sensor, gas supply), but they can continue operating during electrical brownouts that would shut down an electric model.

Safety considerations also differ significantly between types. Electric dryer repairs involve working with potentially lethal 240-volt electricity, requiring careful precautions and proper testing procedures. Gas dryer repairs involve flammable gas and combustion, requiring professional certification for anything beyond basic troubleshooting. Many DIY-comfortable homeowners can safely replace electric dryer components, while gas dryer component replacement should almost always be left to licensed professionals.

Safety First: Critical Precautions Before You Begin

⚠️ STOP: Before you touch any dryer components, understand that you’re working with either 240-volt electricity or natural gas—both of which can cause serious injury or death if mishandled. This isn’t an exaggeration meant to scare you; it’s a reality that kills people every year. Follow these safety rules without exception.

Universal Safety Rules (All Dryers)

🔌 Always Unplug Before Any Internal Work

Don’t trust the power button to disconnect electrical power. Physically unplug the dryer from the wall outlet before removing any panels or touching internal components. In apartments, inform anyone else who has access to ensure no one plugs it back in while you’re working. After unplugging, wait 5 minutes for any capacitors in the control board to fully discharge, though most modern dryers don’t have large capacitors that store dangerous amounts of energy.

🔥 Never Bypass Safety Devices

Thermal fuses, high-limit thermostats, and other safety devices exist to prevent dryer fires—and they work. Some online forums suggest “jumping” a blown thermal fuse with wire or aluminum foil as a temporary fix. This is extraordinarily dangerous. These safety devices cut power when your dryer overheats. Bypassing them means the next time airflow is restricted, temperatures can reach combustion levels for lint or nearby materials, starting a fire.

Always replace blown safety devices with the correct OEM (original equipment manufacturer) parts specified for your model. Aftermarket or generic fuses may have different temperature ratings that don’t provide adequate protection.

🛑 Stop Immediately If You Encounter:

- Burning smells or visible smoke

- Melted wires or components showing heat damage

- Scorch marks on panels or drum

- Unusual sounds like arcing, popping, or buzzing

- Any situation that feels unsafe or beyond your skill level

If you observe any of these conditions, leave the dryer unplugged, don’t attempt to use it, and contact a professional repair service immediately. These are warning signs of serious problems that can lead to fires or electrical shock.

🧹 Clean Before Diagnosing

Lint buildup inside the dryer cabinet, particularly near heating elements and motor areas, is highly combustible. Before working inside the dryer, vacuum thoroughly behind and underneath the appliance, inside the drum area, and around any visible lint accumulation. Use a vacuum with a hose attachment to reach into crevices. Clear your work area of any flammable materials. Working in a clean environment isn’t just good housekeeping—it’s fire prevention.

Gas Dryer-Specific Safety

⚠️ Turn Off Gas Supply

Before any inspection or work on a gas dryer, turn off the gas supply at the shutoff valve on the supply line. The valve handle should be perpendicular to the pipe (forming a T) when closed. This ensures no gas can flow during your work. Even for simple visual inspections, closing the gas valve is a smart precaution.

⚠️ NEVER Attempt Gas Valve or Burner Repairs Without Proper Training

Gas system repairs require specialized knowledge, tools, and in most jurisdictions, professional licensing. Improper gas work can cause:

- Gas leaks leading to explosions (natural gas is odorless; the smell is added as a warning)

- Carbon monoxide poisoning from incomplete combustion (CO is odorless and deadly)

- Flash fires from improper ignition sequences

- Building code violations that affect insurance and home sales

If your diagnosis points to gas valve coils, burner assembly problems, or igniter replacement (if you’re uncomfortable with this), call a licensed professional. The cost of proper repair is insignificant compared to the potential consequences of improper gas work.

⚠️ If You Smell Gas:

- Don’t flip any switches or create sparks (including doorbell buttons)

- Don’t use phones inside the building

- Evacuate immediately, leaving the door open

- Call your gas company (PG&E in San Francisco: 1-800-743-5000) from a safe distance outside

- Don’t return to the building until professionals declare it safe

Gas leaks are not DIY situations. Ever.

⚠️ Install Carbon Monoxide Detector

California law requires carbon monoxide detectors in homes with gas appliances. Install a CO detector in the room with your gas dryer or in an adjacent room. Test it monthly and replace the unit every 5-7 years as recommended by manufacturers. Carbon monoxide from incomplete combustion is odorless, colorless, and deadly. A detector provides critical early warning.

Electric Dryer-Specific Safety

⚡ 240V Can Kill Instantly

Standard household outlets provide 120 volts, which can cause serious injury. Electric dryers use 240 volts—double the voltage—which has killed countless people. The higher voltage means current flows through your body more easily, traveling through your heart to ground. At 240 volts, you don’t get a second chance. There’s no “I’ll be careful” that makes this safe—only proper procedures.

⚡ Circuit Breaker OFF Isn’t Enough

Some people think turning off the circuit breaker provides adequate protection. It doesn’t, for several reasons:

- Breakers can fail or be mislabeled

- Someone else might turn it back on

- You might switch the wrong breaker

- Voltage can still be present from backfeeding in certain wiring situations

Always physically unplug the dryer. If you absolutely must work on a hardwired dryer, use a non-contact voltage tester to verify no power is present before touching any wires.

⚡ Never Work in Wet Conditions

Water conducts electricity exceptionally well. Working with wet hands, on a wet floor, or in any damp conditions dramatically increases electrocution risk. Ensure your hands are completely dry, the floor is dry, and no water sources are nearby. Remove jewelry, particularly rings and watches, which conduct electricity and can cause severe burns if they contact live circuits.

San Francisco Building-Specific Concerns

Many San Francisco buildings were constructed before modern electrical codes existed. Older wiring, shared circuits between apartments, outdated electrical panels, and aluminum wiring in buildings from the 1960s-70s all add complexity and risk. If you’re in an apartment building, understand that electrical systems may be non-standard or deteriorated.

Additionally, many San Francisco apartment leases explicitly prohibit tenant appliance repairs due to liability concerns. Before starting any work, check your lease agreement. Some landlords require that they arrange all appliance repairs to ensure licensed professionals perform the work and to maintain insurance coverage. Violating these clauses could affect your security deposit or lease terms.

When in doubt—about safety, your skill level, or building restrictions—consult a professional. The few hundred dollars you might save on DIY repair isn’t worth injury, property damage, or lease violations.

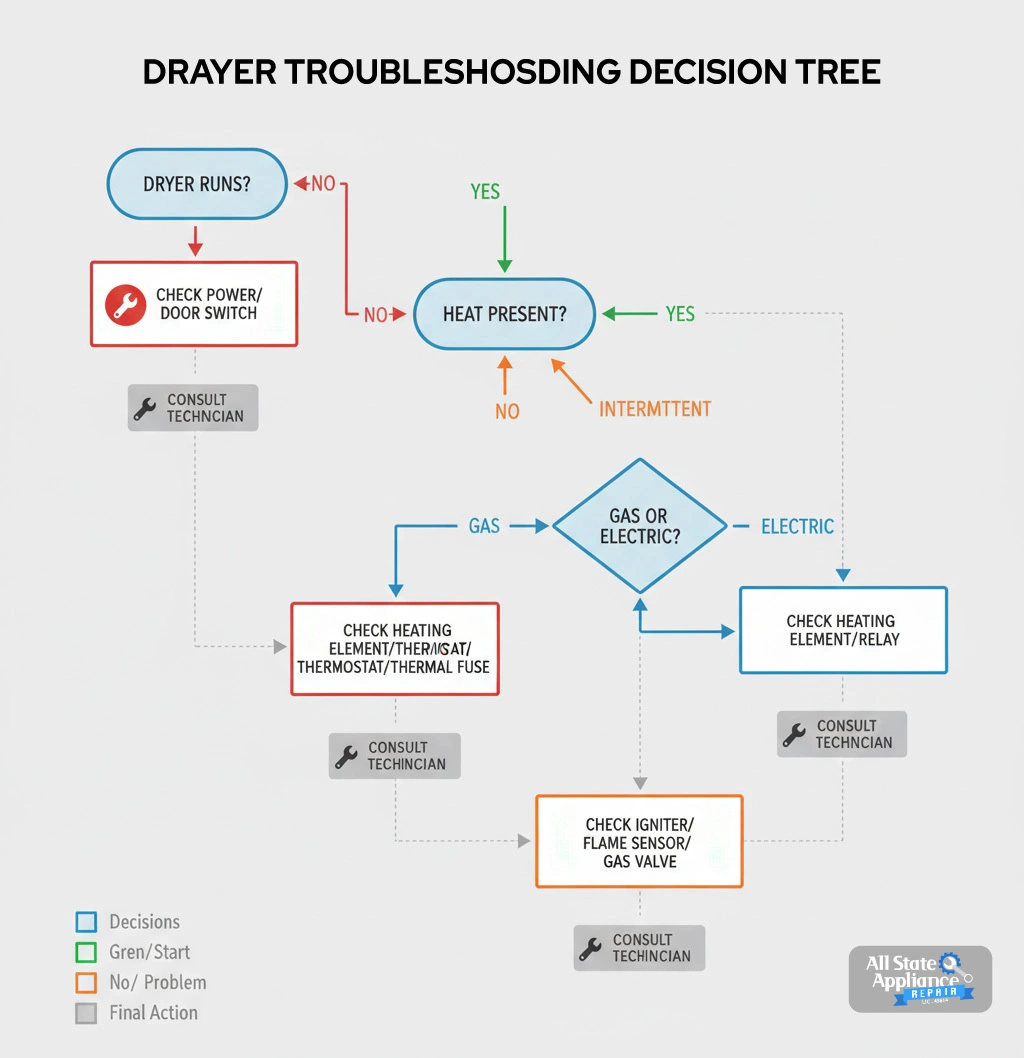

Step-by-Step Troubleshooting Guide

Follow this systematic approach, moving from simplest fixes to more complex diagnoses. Even if you plan to call a professional, performing these basic checks will help you communicate the problem accurately and potentially save on diagnostic fees. Many repair services will walk you through simple troubleshooting over the phone before scheduling a service call.

Simple Checks First (Anyone Can Do These)

Step 1: Clean the Lint Screen Thoroughly

Pull out the lint screen and remove all visible lint with your hand. Now perform the water test: run the screen under warm water. If water flows through easily, the screen is clean. If water beads up or drains slowly, the screen has invisible buildup from fabric softener sheets that blocks airflow.

For clogged screens, scrub with dish soap and a soft brush (an old toothbrush works perfectly). Work the brush across the entire mesh surface, creating suds. Rinse thoroughly with hot water until water flows freely through the screen. Shake off excess water and let the screen air dry completely before reinstalling—installing a damp screen can cause moisture sensor issues.

A clogged lint screen reduces airflow by up to 40%, which creates a cascade of problems: restricted airflow causes overheating, overheating triggers the thermal fuse, and a blown thermal fuse cuts power to the heating system. This simple 5-minute cleaning can solve dryer heating problems and prevent future issues.

💡 Pro Tip: Perform the water test monthly, even if your screen looks clean. Waxy buildup from dryer sheets creates an invisible barrier that’s only detectable with the water test. If you use fabric softener sheets regularly, clean your lint screen with soap and water every 4-6 weeks.

Step 2: Inspect the Dryer Vent System

This step requires moving the dryer, so get help if needed—dryers typically weigh 100-150 pounds. Unplug the dryer (and close the gas valve if it’s a gas model), then carefully pull it away from the wall. You’ll need about 3-4 feet of clearance to work comfortably.

Disconnect the vent hose from the back of the dryer by loosening the clamp (usually requires a screwdriver or adjustable wrench). Look inside both the hose and the dryer’s exhaust port. Use a flashlight to see deep into the openings. You’re looking for:

- Lint accumulation (even small amounts restrict airflow)

- Kinks or crushing in flexible vent hose

- Damaged or disconnected sections

- Foreign objects (sometimes birds nest in exterior vents)

If you find lint buildup, remove it with your hands, a vacuum with a hose attachment, or a specialized dryer vent brush (available at hardware stores for $10-20). For flex hose, straighten any kinks—severe kinks that won’t straighten indicate the hose needs replacement.

Now go outside to your dryer’s exterior vent. While someone inside runs the dryer on a heat cycle, feel the airflow coming from the outside vent. Strong, warm air flowing steadily means your vent system is clear. Weak airflow or no airflow indicates a blockage somewhere in the vent system—potentially inside walls if you’re in a multi-story building.

⚠️ San Francisco Apartment Warning: If your dryer vent runs through walls or multiple floors (common in San Francisco multi-unit buildings), you may not be able to reach the entire vent system yourself. Professional vent cleaning services have specialized rotating brush systems that can clear vents up to 50 feet long. This service costs $100-200 but is essential for fire prevention. Consider annual professional cleaning if your vent run exceeds 15 feet or has multiple turns.

Step 3: Verify Dryer Settings

Before assuming a mechanical problem, take 30 seconds to check your control panel carefully. Look for these settings that deliberately prevent heating:

- “Air Fluff”

- “Air Dry”

- “No Heat”

- “Refresh”

- “Fluff”

These cycles are designed to tumble clothes without heat—useful for fluffing pillows, removing wrinkles from hung clothes, or freshening items that don’t need washing. If one of these settings is selected, your dryer is working exactly as intended.

Also check the timer position on mechanical dial models. These dials can be easily bumped, setting an extremely short cycle time. On electronic models, verify you haven’t accidentally selected a “Timed Dry” with only a few minutes programmed.

Ensure you’ve selected a standard heat-producing cycle like “Regular Dry,” “Normal,” “Heavy Duty,” or “Permanent Press.” Set the temperature to “High” or “Normal” (not “Low” or “Delicate,” which might produce heat too subtle to notice on some fabrics).

Step 4: Assess Load Size and Composition

Overloading prevents proper air circulation through your clothes, causing longer dry times and potentially triggering overheating protection. When the drum is packed too tightly, hot air can’t flow between fabric layers, so moisture can’t be effectively removed. The dryer works harder and longer, increasing wear on all components.

Conversely, tiny loads (like a single towel) can confuse moisture sensors on automatic cycles, causing the dryer to shut off prematurely thinking clothes are dry when they’re actually still damp.

Fill the drum about 3/4 full for optimal performance—clothes should tumble freely with space to move. Don’t mix heavy items like bath towels with lightweight fabrics like sheets in the same load. These fabric types have vastly different drying times, so mixing them means either the lightweight items get over-dried (wasting energy and creating excessive lint) or the heavy items stay damp.

If your dryer consistently takes a very long time to dry properly-sized loads on normal settings, that’s a symptom of an underlying problem—not a reason to simply run longer cycles.

Electric Dryer-Specific Troubleshooting

Step 5: Check Both Circuit Breakers

This is the most commonly misunderstood electric dryer issue, so let’s be very clear about what’s happening: your electric dryer needs 240 volts from TWO circuit breakers. Each breaker provides 120 volts. Together, they deliver the 240 volts required to power both the motor (120V) and the heating element (240V).

Here’s where confusion happens: if one breaker trips while the other stays on, the dryer gets only 120 volts. That’s enough to:

- Power the motor (drum spins normally)

- Run the control panel (lights/display work)

- Operate the timer (counts down normally)

- Run the blower fan (air circulates)

But 120 volts is NOT enough to power the heating element. So you’ll observe a dryer that appears completely normal—spinning, counting down, making all its usual sounds—except clothes stay damp because there’s no heat.

How to Check Your Circuit Breakers:

- Locate your home’s electrical panel (often in garage, basement, or utility closet)

- Find the circuit labeled “Dryer” or “Laundry”

- Look for TWO adjacent breakers, often mechanically linked (called a “double breaker”), or two separate single breakers side-by-side

- Both switches must be fully in the ON position

- If either has tripped, it may be in a middle position between ON and OFF

To Reset a Tripped Breaker:

- Don’t just flip it to ON from the middle position

- First push it fully to OFF (you may hear/feel a click)

- Then push it fully to ON

- This ensures proper re-engagement of the breaker mechanism

After resetting, test your dryer. If the breaker trips again immediately or within a few minutes, you have a more serious problem—likely a short circuit in the dryer’s wiring or a grounded heating element—that requires professional diagnosis.

📌 San Francisco Building Note: Older San Francisco buildings, particularly those constructed before 1970, may have Federal Pacific Electric (FPE) or Zinsco electrical panels. These brands are known to have serious safety defects, including breakers that don’t trip properly during overload conditions or that trip unexpectedly. If you have one of these panels and experience repeated breaker trips, consult a licensed electrician about panel replacement. This isn’t just a convenience issue—these panels have been implicated in electrical fires.

Step 6: Test the Thermal Fuse

The thermal fuse is your dryer’s last line of defense against fire. Understanding how it works will help you avoid repeat failures.

What It Does:

The thermal fuse is a small device containing a metal element designed to melt at a specific temperature—usually 185-220°F depending on your dryer model. When your dryer overheats (almost always due to restricted airflow from a clogged vent), temperatures exceed this threshold, the fuse element melts, and the electrical circuit to the heating system permanently opens.

Unlike circuit breakers that can be reset, thermal fuses are one-time devices. Once blown, they must be replaced. This design is intentional: it forces you to address the overheating cause before the dryer will heat again, preventing repeated overheating that could start a fire.

Locating the Thermal Fuse:

Thermal fuse location varies by manufacturer and model, but typical locations include:

- Mounted on the blower housing (where the fan is located)

- On the heating element housing

- On the burner assembly (gas dryers)

- Inside the rear panel or exhaust duct

Search online for “[your dryer brand and model] thermal fuse location” or consult your owner’s manual. Many manufacturers provide free PDF manuals on their websites if you’ve lost your printed copy. YouTube often has videos showing thermal fuse location and replacement for popular dryer models.

Testing Procedure:

What You Need:

- Screwdriver set (to remove access panels)

- Multimeter (digital multimeters cost $15-40 at any hardware store)

- Your dryer’s model number (usually on a sticker inside the door frame)

Testing Steps:

- Unplug the dryer completely

- Remove the appropriate panel to access the thermal fuse (often the rear panel, but varies by model)

- Locate the thermal fuse – it’s typically a small white, black, or silver component about the size of your thumb with two wire connectors

- Disconnect both wires from the fuse terminals (take a photo first so you remember which wire goes where)

- Set your multimeter to “Continuity” mode (symbol looks like “)))” or use the ohms/Ω setting)

- Touch the multimeter probes to the fuse terminals (the metal parts where wires connect)

- Read the result:

- Good fuse: Meter reads 0 ohms or beeps (indicating continuity – electricity can flow through)

- Blown fuse: Meter reads “OL” (overload), “1”, or infinity symbol (no continuity – circuit is open)

A blown thermal fuse shows infinite resistance because the internal element has melted, creating a permanent break in the circuit.

Replacement: The Critical Part

If your thermal fuse is blown, replacement is straightforward: remove the old fuse, install the new one, and reconnect the wires. The part costs $10-30 depending on your dryer model. Order the exact replacement using your model number—thermal fuses have specific temperature ratings that must match your dryer’s requirements.

However—and this is critically important—you MUST identify and fix what caused the overheating before installing the new fuse. In 95% of cases, the cause is a clogged vent system. If you simply replace the fuse without cleaning the vent, the new fuse will blow again within hours or days because the underlying overheating condition still exists.

Before installing a new thermal fuse:

- Thoroughly clean the lint screen

- Inspect and clean the entire vent system from dryer to exterior

- Ensure the vent hose has no kinks or restrictions

- Verify the exterior vent cap opens freely when the dryer runs

- Consider professional vent cleaning if your system is long or complex

Only after confirming proper airflow should you install the new thermal fuse. This approach fixes the root cause, not just the symptom.

⚠️ NEVER “Bypass” or “Jump” a Thermal Fuse: Some online sources suggest connecting wires directly to bypass a blown fuse as a “temporary” fix. This is extraordinarily dangerous. The thermal fuse prevents dryer fires by cutting power when overheating occurs. Bypassing it means the next time conditions cause overheating, temperatures can reach combustion levels for accumulated lint, starting a fire. No DIY repair is worth this risk.

Step 7: Inspect the Heating Element

The heating element is the component that actually generates heat in electric dryers. Understanding how it works and how it fails will help you diagnose problems accurately.

What It Is:

Electric dryer heating elements consist of nichrome wire (a nickel-chromium alloy) wound into a tight coil inside a metal housing. When 240 volts flows through the wire, electrical resistance creates intense heat—the coil glows red like a stove burner, reaching temperatures of 400-500°F. Air blown across this coil heats up before circulating through your clothes.

How Heating Elements Fail:

Heating elements fail through repeated thermal stress. Every time you run a dryer cycle, the element heats from room temperature to 400-500°F, then cools back down. This expansion and contraction eventually weakens the metal, particularly at stress points near connection terminals or where the coil is anchored. Eventually, the wire breaks—creating an open circuit that prevents current flow and eliminates heat production.

Elements can also fail by shorting to the metal housing. If a coil breaks loose from its anchors and touches the grounded metal casing, it creates a direct path to ground. This usually trips the circuit breaker immediately when the heating cycle starts.

Visual Inspection:

Access the heating element by removing the appropriate panel on your dryer—location varies by brand. Common locations include behind the front lower panel, behind the rear panel, or inside a removable housing beneath the drum. Consult your service manual or search online for your specific model.

Once you can see the heating element, look for:

- Visible breaks in the coil – gaps in the wire where it has snapped

- Coil touching the housing – broken elements often droop and contact the metal casing

- Blistered or discolored metal – indicates severe overheating

- Burn marks or scorching – signs of electrical arcing or shorting

A bright flashlight or work light helps, as heating element housings are often in dimly-lit areas of the dryer cabinet.

Multimeter Testing:

For definitive diagnosis, test the heating element with a multimeter:

- Unplug the dryer

- Access the heating element and locate the terminals (where wires connect)

- Disconnect the wires from the element terminals

- Set multimeter to ohms (Ω)

- Touch probes to the element terminals

- Read the resistance:

- Good element: Usually reads 10-50 ohms (exact value varies by model—check your specifications)

- Broken element: Reads “OL” (overload) or infinity—indicating an open circuit

- Shorted element: Reads 0 or very low resistance

Additionally, test for shorts to ground: 7. Touch one probe to an element terminal 8. Touch the other probe to the metal housing 9. Should read infinite/OL (no connection between element and housing) 10. If you get any reading, the element is shorted to ground and must be replaced

Replacement Considerations:

Heating elements cost $30-200 depending on your dryer brand and model. Whirlpool, Kenmore, and GE elements tend to be more affordable ($30-80), while high-end brands like Bosch or Miele can cost $150-200. Always purchase the exact element specified for your model number—elements are not universal.

Replacement requires moderate DIY skill. You’ll need to:

- Remove the appropriate access panel

- Disconnect electrical wires (photograph connections first)

- Remove mounting screws or brackets

- Remove the old element

- Install the new element in the same orientation

- Reconnect wires to the correct terminals

- Reassemble panels

- Test operation

If you’re comfortable with these steps and have basic hand tools, this is a reasonable DIY project that can save $100-200 in labor charges. However, if you’re uncomfortable working with 240-volt appliances or unsure about the process, professional installation runs $150-400 total in San Francisco, including parts and labor. Many repair services waive their diagnostic fee if you proceed with the repair.

Step 8: Check Thermostats and Temperature Sensors

Electric dryers use multiple thermostats to regulate temperature and provide safety shutoffs. When these fail, you may experience no heat, insufficient heat, or overheating that damages clothes.

Types of Thermostats in Your Dryer:

Cycling Thermostat:

- Opens and closes contacts to maintain desired temperature

- Located on the blower housing or heating element assembly

- Cycles on/off throughout the drying process

- When it opens (breaks circuit), heating stops; when it closes, heating resumes

- Typical operating range: Opens at 130-150°F, closes at 100-120°F

High-Limit Thermostat:

- Safety device that opens if temperature exceeds safe limits (usually 250-280°F)

- Should normally be closed (conducting electricity)

- Opens only during overheating conditions

- May or may not reset when temperature drops (depends on model)

- Located on heating element housing or exhaust duct

Thermal Cutoff (Similar to Thermal Fuse):

- Another one-time safety device

- Blows at extreme temperatures (typically 280-320°F)

- Cannot be reset—must be replaced

- Often found alongside high-limit thermostats

Testing Thermostats:

Testing thermostats requires understanding their normal state at room temperature:

- Unplug the dryer

- Locate thermostats (consult service manual for your model)

- Disconnect wires from thermostat terminals

- Set multimeter to continuity or ohms

- Test each thermostat:

- High-limit thermostat: Should show continuity (0 ohms) at room temperature—it should be closed

- Cycling thermostat: May or may not show continuity at room temperature depending on its setpoint—this is normal

- Thermal cutoff: Should show continuity (0 ohms) at room temperature

If a high-limit thermostat or thermal cutoff shows no continuity (infinite resistance) at room temperature, it has tripped and needs replacement.

When Thermostats Fail:

Thermostat failure symptoms include:

- Dryer doesn’t heat at all (thermostat stuck open)

- Dryer overheats and shrinks/damages clothes (thermostat stuck closed)

- Heating is intermittent (failing thermostat contacts)

- Clothes take much longer to dry (thermostat opening too early)

Thermostats are relatively inexpensive ($15-40) and straightforward to replace if you can access them. However, repeated thermostat failures indicate an underlying problem—usually restricted airflow causing overheating—that must be addressed.

Gas Dryer-Specific Troubleshooting

⚠️ IMPORTANT DISCLAIMER: The following steps are for DIAGNOSIS only. Gas appliance component replacement and repairs should be performed by licensed professionals due to serious safety hazards including gas leaks, explosions, fires, and carbon monoxide poisoning. Use this information to understand your dryer’s problem and communicate effectively with repair technicians, but call a professional for actual repairs.

Step 9: Verify Gas Supply

Before assuming component failure, verify that gas is actually flowing to your dryer.

Check the Gas Shutoff Valve:

Locate the gas shutoff valve on the supply line behind or beside your dryer. This valve controls whether gas can flow from your home’s gas system to the dryer. The valve handle position tells you whether it’s open or closed:

- OPEN (gas flowing): Handle is PARALLEL to the gas pipe

- CLOSED (no gas flow): Handle is PERPENDICULAR to the pipe (forming a T or cross)

If the handle is perpendicular, someone has closed the valve—perhaps during cleaning, moving furniture, or service work on another appliance. Simply turn the handle clockwise or counterclockwise (depending on orientation) until it’s parallel with the pipe. You should feel a positive stop when the valve is fully open.

Confirm Gas Is Flowing to Your Home:

Test other gas appliances in your home. If your gas stove, water heater, or furnace is working normally, gas is flowing to your building. If nothing works, the problem is your building’s gas supply—possibly:

- Gas meter shut off (check if handle is perpendicular to pipes)

- Service interruption (call PG&E at 1-800-743-5000)

- Account payment issue

- Building-wide shutoff for repairs

Smell Test:

Natural gas and propane are odorless, but utilities add mercaptan—a chemical with a distinctive rotten egg or sulfur smell—as a safety warning. If you smell this odor at any point:

- Don’t flip switches, light matches, or create any sparks

- Don’t use phones inside the building (cordless phones and cell phones can spark)

- Leave the building immediately, leaving the door open to ventilate

- Call your gas company from outside (PG&E: 1-800-743-5000)

- Don’t return until professionals clear the building as safe

Gas leaks are never DIY situations. Even if the leak seems small, gas can accumulate in enclosed spaces and ignite explosively from the smallest spark.

Step 10: Observe the Ignition Sequence

Understanding your gas dryer’s normal operation helps you identify exactly which component has failed. This diagnosis can be performed safely without touching any components.

Normal Gas Dryer Heating Sequence:

When you start a drying cycle on a gas dryer, here’s what should happen:

- Timer starts, drum begins rotating (30-60 seconds of tumbling without heat is normal while dryer tests for proper conditions)

- Igniter begins glowing (visible through viewing ports on some models, or you may need to carefully look through access panels—don’t touch anything, just observe)

- Igniter glows bright orange/red (takes 30-90 seconds to reach full temperature—approximately 2500°F)

- Gas valve opens (you may hear a subtle click or change in sound)

- Gas flows to burner (may hear very faint hissing)

- Igniter lights the gas (you’ll hear a soft “whoosh” as flame ignites)

- Blue flame appears across the burner assembly (visible through viewing ports)

- Flame cycles on/off as needed throughout drying cycle to maintain temperature

Each step must occur in sequence. When one component fails, the sequence stops at that point, giving you diagnostic information.

Diagnostic Scenarios:

Scenario 1: No Glow, No Flame

What’s Happening: The igniter isn’t receiving power or has completely failed.

Likely Causes:

- Blown thermal fuse (same as electric dryers—cuts power to entire heating circuit)

- Failed igniter (complete failure—no glow at all)

- Bad flame sensor (telling control board not to attempt ignition)

- Control board failure (not sending power to ignition system)

Next Steps: Test the thermal fuse first (same procedure as electric dryers). If thermal fuse is good, you need professional diagnosis of the igniter, flame sensor, or control board.

Scenario 2: Igniter Glows But No Flame Appears

What’s Happening: The igniter is working (glowing proves it’s receiving power and heating), but gas isn’t flowing to the burner.

Likely Causes:

- Faulty gas valve coils (coils aren’t opening the valve despite igniter heat)

- Closed gas supply valve (check first—simplest cause)

- Gas valve mechanism stuck or failed

- Insufficient gas pressure (rare, but possible in some building systems)

What You’ll Observe: The igniter will glow continuously for 3-4 minutes, then the control system times out and shuts off the igniter. After a brief pause, it tries again. This cycle repeats because the system is waiting for the flame sensor to detect heat, which never happens because no gas is burning.

Next Steps: Verify gas supply valve is open. If yes, you need professional diagnosis and likely gas valve coil replacement. This is NOT a DIY repair.

Scenario 3: Flame Ignites Then Immediately Goes Out

What’s Happening: Gas lights successfully but the flame sensor doesn’t detect proper combustion, so the control board shuts off gas flow as a safety measure.

Likely Causes:

- Dirty or failed flame sensor (not detecting heat from flame)

- Weak flame from partially clogged burner

- Airflow issues causing flame instability

- Gas pressure problems

What You’ll Observe: You’ll see (and hear) the flame ignite, but within 1-5 seconds, it goes out. The igniter then begins glowing again to attempt another cycle. This pattern repeats.

Next Steps: Professional service needed. Flame sensor cleaning or replacement, burner cleaning, or gas pressure adjustment may be required.

Scenario 4: Weak Yellow Flame Instead of Strong Blue Flame

What’s Happening: Gas is burning, but combustion isn’t efficient due to incorrect air/fuel mixture.

Likely Causes:

- Dirty burner assembly (lint or dust blocking air intake)

- Incorrect gas pressure (too low or too high)

- Conversion between natural gas and propane not done properly

Why This Matters: Yellow flames indicate incomplete combustion, which produces carbon monoxide. This is a serious safety issue.

Next Steps: Turn off the dryer immediately and call a professional. Do not use the dryer until the burner is properly cleaned and adjusted. Ensure your carbon monoxide detector is working.

Step 11: Inspect the Igniter (Visual Only)

The igniter can be viewed (carefully, without touching anything) while the dryer attempts to heat. Some dryers have small viewing windows or ports that let you observe the igniter and burner. Others require removing a lower access panel to see into the burner area.

What to Look For:

Normal Igniter:

- Glows bright, uniform orange-red color

- Reaches full brightness within 60-90 seconds

- Maintains steady glow (doesn’t flicker or dim)

- No visible cracks or damage to ceramic element

Failing Igniter:

- Glows dim orange or yellow (not hot enough to open gas valve)

- Takes longer than 90 seconds to reach maximum brightness

- Flickers or changes intensity

- Visible cracks in ceramic (even hairline cracks affect performance)

- Broken or damaged mounting

Failed Igniter:

- Doesn’t glow at all (complete failure)

- Glows for a moment then goes dark (internal break)

Why Igniters Fail:

Igniters fail from thermal stress—repeated heating to 2500°F and cooling back to room temperature eventually causes the ceramic or silicon carbide material to crack or weaken. Typical igniter lifespan is 3-5 years with regular use, though some last longer. Once cracks form, even microscopic ones, the igniter can’t reach the temperature needed to open the gas valve.

Replacement Considerations:

Igniters cost $20-60 depending on your dryer model. Replacement involves:

- Turning off gas supply

- Unplugging dryer

- Accessing burner assembly

- Disconnecting wires

- Removing mounting screws

- Installing new igniter in exact same position

- Reassembling and testing

While mechanically simple, igniter replacement involves working around gas components. Many DIY-capable homeowners are comfortable with this repair, but if you have any uncertainty about working near gas systems, professional installation costs $150-350 total, including parts and labor.

Step 12: When to Stop and Call a Professional

For gas dryers, the line between safe DIY diagnosis and professional-required repair is clear. Call a licensed appliance repair technician for:

Immediate Professional Help Required:

- Any gas odor present (after safely evacuating and calling gas company)

- Igniter doesn’t glow at all (after confirming thermal fuse is good)

- Igniter glows but no flame appears (gas valve issue)

- Flame appears but immediately goes out (flame sensor issue)

- Yellow flame instead of blue (combustion problem creating CO)

- Repeated thermal fuse failures (underlying problem causing overheating)

- Any work on gas valve, burner assembly, or gas line

- Carbon monoxide detector alerts

Why Professional Service Is Essential:

Gas appliances in California require specific certifications for repair work. Licensed technicians have:

- Training in gas system safety and combustion principles

- Proper tools for gas pressure testing and leak detection

- Knowledge of building codes and safety standards

- Insurance coverage for gas-related work

- Access to manufacturer technical specifications

Improper gas dryer repairs can cause:

- Gas leaks leading to explosions

- Carbon monoxide poisoning from incomplete combustion

- Fire from improper ignition sequences

- Building code violations affecting insurance and property value

The cost of professional repair ($150-400 for typical gas dryer heating problems) is insignificant compared to the potential consequences of improper gas work. When in doubt, call a pro.

When to Call a Professional in San Francisco

While many dryer heating issues are DIY-friendly for those comfortable with basic tools and troubleshooting, some situations clearly require professional expertise, specialized equipment, or legal certifications. Here’s how to know when to set down your multimeter and pick up the phone.

Clear Professional Territory

Gas Dryer Repairs Beyond Basic Troubleshooting:

- Any work involving gas valves, coils, or gas line connections

- Burner assembly cleaning or replacement

- Gas pressure testing or adjustment

- Igniter replacement (if you’re uncomfortable working near gas systems)

- Flame sensor cleaning or replacement

- Repeated thermal fuse failures indicating underlying combustion problems

- Converting between natural gas and propane

Complex Electrical Issues:

- 240V wiring repairs or modifications

- Electrical panel or circuit breaker replacement

- Terminal block replacement (where power cord connects to dryer)

- Control board or user interface failures

- Repeated circuit breaker tripping despite good heating element

Multiple Failed Components:

- When diagnostic testing reveals 2+ failed parts

- When replacing one component doesn’t solve the problem

- When you can’t identify which component has failed after thorough troubleshooting

When DIY Attempts Haven’t Worked:

- You’ve replaced the obvious failed part but problem persists

- Don’t have necessary tools (multimeter, socket set, specialty tools)

- Uncomfortable with the repair complexity or safety risks

- Time constraints make professional repair more practical

Warranty and Insurance Considerations:

- Dryer still under manufacturer warranty (DIY repairs often void warranty)

- Home warranty or appliance protection plan coverage

- Rental property where landlord must arrange repairs

- Homeowner’s insurance may cover certain appliance failures

What to Expect from San Francisco Repair Services

Understanding the professional repair process helps you know what’s reasonable and what’s not.

Typical Service Call Sequence:

1. Initial Contact and Scheduling Most San Francisco appliance repair services offer:

- Same-day or next-day appointments

- 2-4 hour arrival windows (some offer text alerts)

- Evening and weekend availability (often at premium rates)

- Phone troubleshooting before scheduling (may solve simple issues)

2. Diagnostic Visit Technician will:

- Inspect the dryer and test operation

- Use diagnostic tools (multimeter, gas pressure gauge, etc.)

- Identify failed components and root causes

- Provide written estimate for repairs

- Explain the problem and repair options

Diagnostic fees typically run $75-125 in San Francisco. Many services waive this fee if you proceed with the repair.

3. Repair Completion If you approve the estimate:

- Most repairs completed same visit if parts are on truck

- Parts not in stock ordered with return visit scheduled

- Typical repair time: 30-90 minutes depending on complexity

- Technician tests dryer thoroughly after repair

- Provides receipt with parts and labor itemized

4. Warranty Coverage Reputable services offer:

- Minimum 90-day warranty on labor

- 1-year warranty on parts (often manufacturer warranty)

- Return visit at no charge if same problem recurs within warranty period

San Francisco Pricing Context

Bay Area labor rates and cost of living affect appliance repair pricing. Here’s what to expect:

Common Gas and Electric Dryer Repair Costs:

Thermal Fuse Replacement: $100-200 total

- Part: $10-30

- Labor: $75-125

- Includes testing other components to confirm diagnosis

Heating Element Replacement (Electric): $150-400 total

- Part: $30-200 (varies by brand)

- Labor: $95-200

- Usually includes thermostat inspection

Gas Igniter Replacement: $150-350 total

- Part: $20-60

- Labor: $100-250 (gas work commands premium)

- Includes gas pressure verification

Gas Valve Coils Replacement: $200-450 total

- Parts: $40-100

- Labor: $150-300

- More complex than igniter replacement

Complete Dryer Vent Cleaning: $100-250

- Varies by vent length and accessibility

- Includes rotary brush cleaning and airflow testing

- Essential if vent runs through walls/floors in SF buildings

Control Board Replacement: $200-500 total

- Part: $100-300

- Labor: $100-200

- Often requires programming/configuration

Labor Rate Context: San Francisco appliance technician rates run $95-150 per hour, reflecting Bay Area cost of living and business expenses (vehicle, insurance, licensing, inventory). Same-day and emergency service typically adds $50-100 premium. Holiday and weekend service may cost 1.5-2x standard rates.

Ways to Reduce Costs:

- Schedule during normal business hours (weekday mornings often available)

- Perform simple troubleshooting before calling (saves diagnostic time)

- Get estimates from 2-3 services (prices vary significantly)

- Ask about senior, military, or first-time customer discounts

- Bundle multiple appliance repairs if needed

Choosing the Right San Francisco Appliance Repair Service

Not all repair services are equal. Use these criteria to identify reputable professionals:

Essential Qualifications:

✅ Licensed and Insured

- Verify California contractor license at cslb.ca.gov

- Confirm liability insurance (protects you if damage occurs)

- Workers compensation insurance (protects you from liability)

✅ Gas Appliance Certification

- EPA Section 608 certification for gas work

- Manufacturer-specific training (if applicable)

✅ Established Local Presence

- Physical business address in Bay Area

- Years in business (5+ years indicates stability)

- Better Business Bureau rating

✅ Transparent Pricing

- Written estimates before work begins

- Clear explanation of what’s included

- No pressure for immediate payment

✅ Warranty on Work

- Minimum 90-day labor warranty

- Parts warranty (often 1 year)

- Clear terms in writing

✅ Positive Customer Reviews

- 4+ stars on Google/Yelp

- 50+ reviews (larger sample size more reliable)

- Recent reviews (within past 6 months)

- Check how business responds to negative reviews

Red Flags to Avoid:

❌ Cannot provide license number or “working on getting licensed” ❌ Requests full payment before starting work ❌ Reluctant to provide written estimates ❌ No physical business address (works from personal vehicle only) ❌ Insists on cash-only payment ❌ Can’t clearly explain what’s wrong or why repair costs what it does ❌ Tries to sell unnecessary additional repairs ❌ Negative reviews mention incomplete work, no-shows, or hidden fees

San Francisco-Specific Considerations:

In SF, also consider:

- Parking availability (some technicians charge for difficult parking situations)

- Apartment access requirements (building codes, service elevator availability)

- Familiarity with older building quirks (many SF homes have unique challenges)

- After-hours availability (important for emergency situations)

Getting the Best Service:

When calling for service, provide:

- Dryer brand and model number (found on sticker inside door frame)

- Clear description of the problem

- What you’ve already checked

- Your address (some areas cost more to service)

- Your schedule flexibility (morning weekday appointments often available sooner)

Being prepared and informed helps technicians diagnose efficiently and may reduce service call time.

Preventing Future Dryer Heating Problems

An ounce of prevention is worth a pound of repair bills—or in San Francisco’s case, $200-400 in repair costs. Follow this maintenance schedule to keep your dryer heating efficiently, safely, and reliably for its full lifespan of 10-15 years.

After Every Load

Remove All Lint from Screen Don’t just tap the screen—use your fingers to peel off the entire lint layer, including edges. Even a thin film of lint reduces airflow by 20-30%. This 5-second task is the single most important thing you can do for dryer performance and safety.

Check Drum for Forgotten Items Coins, crayons, pens, and small items damage drum fins, clog vents, and cause rattling. Remove everything before starting the next load. Melted crayons on the drum can transfer to subsequent loads and are difficult to clean.

Leave Door Open 30 Minutes After cycles complete, prop the door open to let moisture evaporate from the drum and door seal. This prevents mildew growth and extends seal lifespan. In San Francisco’s generally dry climate, this is less critical than in humid areas, but it’s still good practice.

Monthly Maintenance Tasks

Deep Clean Lint Trap Even clean-looking lint screens accumulate invisible waxy residue from dryer sheets and liquid fabric softener. Once monthly, wash your lint screen with:

- Hot water

- Dish soap (Dawn or equivalent)

- Soft brush (old toothbrush works perfectly)

Scrub both sides of the mesh, creating suds. Rinse thoroughly under hot water. Perform the water test: water should flow freely through the screen. If it beads up, scrub more. Let air dry completely before reinstalling.

This removes invisible buildup that can reduce airflow by up to 40% even when the screen looks clean.

Vacuum Around Door Seal Lint accumulates in the crevices around the door seal, eventually working into the door switch and seal itself. Use a vacuum with hose attachment to clean:

- Door seal groove

- Door strike area

- Lint trap housing (remove screen and vacuum inside)

Check Vent Hose Connections Pull the dryer away from the wall and inspect:

- Vent hose clamps are tight (snug but not over-tightened)

- No kinks forming in flexible hose

- Hose hasn’t come loose at either connection

- No visible damage to vent material

Reconnect or replace if needed. Vent hose problems develop gradually as dryers vibrate during use.

Wipe Moisture Sensors Most modern dryers have moisture sensors—metal strips inside the drum that detect when clothes are dry. Over time, fabric softener residue builds up on these sensors, causing inaccurate readings. The dryer may shut off prematurely, leaving clothes damp, or run too long, over-drying them.

Clean sensors monthly:

- Locate the sensor strips (usually inside front rim of drum, look like two small metal bars)

- Dampen cloth with rubbing alcohol or white vinegar

- Wipe sensors thoroughly until no residue remains

- Buff dry with clean cloth

This simple task dramatically improves auto-dry cycle accuracy.

Every 3-6 Months

Pull Out and Vacuum Behind Dryer Lint escapes from every dryer, accumulating behind and beneath the unit. Every few months:

- Unplug dryer (and close gas valve for gas models)

- Pull away from wall

- Vacuum floor, wall, and back of dryer thoroughly

- Use crevice tool to reach tight spaces

- Check that nothing has fallen behind dryer (socks, small items)

This also lets you inspect the power cord and vent connections.

Inspect Vent Hose for Damage Flexible vent hoses deteriorate over time, especially foil or vinyl types. Look for:

- Cracks or holes

- Separated seams

- Crushed or permanently kinked sections

- Loose or missing clamps

Replace damaged vent hose immediately. Consider upgrading to semi-rigid aluminum vent pipe, which is more durable and provides better airflow than flexible foil hose.

Check External Vent Cap Go outside and locate your dryer’s exhaust vent. Inspect for:

- Lint buildup around the vent cap

- Flapper door stuck open or closed

- Bird nests or debris blocking opening

- Damage to vent cap allowing pest entry

In San Francisco, birds particularly love warm dryer vents for nesting. Install a pest guard if needed, ensuring it doesn’t restrict airflow.

Verify Door Seal Integrity The door gasket creates a seal that keeps heated air inside the drum. Inspect for:

- Cracks or tears

- Sections pulling away from door

- Hardening or loss of flexibility

- Visible lint escaping during operation

Replace worn door seals to maintain efficiency. Poor seals reduce heating efficiency by 15-25%.

Annual Professional Maintenance

While DIY maintenance handles most needs, professional service catches problems before they become expensive repairs.

Professional Dryer Vent Cleaning

This is especially important in San Francisco apartments and homes where dryer vents run through walls, between floors, or make multiple turns. Professional vent cleaning includes:

- Rotary brush cleaning that reaches 30-50 feet through vent systems

- Airflow testing before and after cleaning to verify improvement

- Exhaust hood inspection and cleaning

- Vent damage assessment (crushing, disconnections, or deterioration)

Cost: $100-250 depending on vent length and accessibility

Why It Matters: Even with excellent lint screen maintenance, some lint always escapes into the vent. Over time, this builds up, especially in long horizontal runs or runs with 90-degree turns. Professional cleaning removes this buildup, preventing fire hazards and maintaining efficiency.

Fire departments strongly recommend annual vent cleaning. In some San Francisco rental properties, landlords are required to arrange annual vent cleaning as part of fire prevention measures.

Full Appliance Inspection

A comprehensive professional inspection includes:

- Testing all heating components (elements, igniters, thermostats)

- Verifying proper gas pressure (gas models)

- Inspecting electrical connections

- Testing safety devices

- Checking drum support and belt condition

- Lubricating as needed

- Identifying wear before failures occur

Cost: $75-150 (often combined with vent cleaning for package discount)

Return on Investment: This preventive service costs $175-350 annually but prevents $300-600 repair bills and extends dryer lifespan by 3-5 years. A $1,000 dryer that lasts 15 years instead of 10 years saves you $333 in replacement costs, not counting avoided repair bills.

Best Practices for Dryer Longevity

Beyond scheduled maintenance, how you use your dryer affects its lifespan and reliability.

Loading Best Practices:

- Fill drum 3/4 full maximum (overloading strains components)

- Sort loads by fabric weight (don’t mix towels and t-shirts)

- Don’t dry single items (confuses moisture sensors)

- Shake out items before loading (prevents tangling that extends cycles)

Operating Best Practices:

- Use lowest heat setting that works (high heat wears components faster)

- Don’t interrupt cycles unnecessarily (thermal cycling stresses parts)

- Don’t add “just one more item” mid-cycle (disrupts moisture detection)

- Actually check your pockets (coins damage drum, markers cause stains, tissues create lint nightmares)

Temperature Selection:

- High heat: Heavy items like towels and bedding

- Medium heat: Everyday items like cotton shirts and jeans

- Low heat: Delicates, activewear, anything with elastic

- Air fluff (no heat): Pillows, stuffed animals, refreshing hung clothes

Using appropriate heat settings extends both dryer life and clothing life. High heat on delicates shrinks clothes and wears out your heating element faster.

Environmental Considerations:

- Ensure 4-6 inches of clearance around dryer for ventilation

- Don’t block dryer vents with storage boxes or furniture

- Maintain room temperature above 55°F (dryers work harder in cold rooms)

- Install in well-ventilated areas when possible

In San Francisco, dryers in basements or garages may experience temperature extremes that affect performance. Ensure adequate ventilation.

San Francisco-Specific Tips

Climate Considerations:

Bay Area’s mild, low-humidity climate offers advantages for dryer operation:

- Clothes dry faster than in humid regions (Houston, Miami)

- Less pre-drying moisture means shorter cycle times

- Reduced mildew risk inside drum and seals

Adjust drying times accordingly—many San Francisco residents find their clothes dry 10-20% faster than the automatic cycle suggests. Consider using timed dry cycles set slightly shorter than usual.

Apartment and Building Challenges:

San Francisco’s high density of apartment buildings creates unique maintenance considerations:

Stacked Washer/Dryer Units:

- Ensure adequate ventilation despite tight spaces

- More difficult to access for maintenance

- Consider semi-annual professional inspection

- Vibration can work hose connections loose faster

Shared Vent Systems:

- Some older buildings have shared or complex vent routing

- Clogs in shared systems affect multiple units

- Building management may need to arrange cleaning

- Check your lease for maintenance responsibilities

Older Building Electrical:

- Buildings constructed before 1970 may have undersized circuits

- Federal Pacific or Zinsco panels common in older SF buildings

- Frequent breaker trips may indicate inadequate electrical service

- Consult electrician about panel upgrades if needed

Building Access:

- Coordinate with building management for service elevator use

- Provide entry codes or buzz-in information to repair services

- Consider parking challenges when scheduling service

- Some services charge extra for difficult access situations

By following this maintenance schedule and operating practices, you’ll minimize heating problems, reduce repair costs, prevent fires, and extend your dryer’s lifespan significantly.

Frequently Asked Questions

Here are detailed answers to the most common questions San Francisco residents ask about dryer heating issues.

Why is my dryer not heating up?

The most common reason a dryer stops heating is a clogged vent system, accounting for 35-40% of all heating failures across both gas and electric models. When lint blocks proper airflow through the exhaust system, your dryer overheats internally and triggers the thermal fuse—a one-time safety device that permanently cuts power to the heating circuit to prevent fires. Once this fuse blows, the dryer will run normally (drum spinning, timer counting down) but produce no heat whatsoever.

Other frequent causes include tripped circuit breakers in electric models, where the dryer receives only 120 volts instead of the required 240 volts, causing the motor to run but the heating element to remain cold. Failed heating elements are responsible for about 10% of electric dryer heating problems, while bad igniters cause approximately 10% of gas dryer heating failures.

Before assuming major component failure, always start with the basics: thoroughly clean your lint screen using the water test (water should flow freely through the mesh), inspect the entire vent system from dryer to outside exhaust for blockages or kinks, and verify your circuit breakers are fully in the “on” position (electric dryers require two breakers). These simple checks resolve roughly half of all dryer heating complaints and cost nothing but a few minutes of your time.

How do I fix a dryer not heating?

Start with the easiest solutions and progress to more complex repairs only if needed. First, clean the lint screen thoroughly—not just removing visible lint, but washing it with dish soap and hot water to remove invisible fabric softener residue. Perform the water test by running water through the screen; if it beads up or drains slowly, scrub until water flows freely.

Next, check the entire vent system. Disconnect the vent hose from the back of the dryer and inspect for lint buildup or kinks. Go outside and feel the airflow from the exterior vent while someone runs the dryer—strong, warm air indicates a clear vent, while weak or absent airflow signals a blockage somewhere in the system.

For electric dryers, verify that both circuit breakers are fully engaged in the “on” position. Electric dryers require 240 volts from two breakers, and if just one has tripped, the drum will spin but no heat will be produced.

If these simple fixes don’t restore heat, you’ll need to test the thermal fuse with a multimeter. This small safety device blows when the dryer overheats and must be replaced if defective. However, it’s critical to identify and fix what caused the overheating—almost always a clogged vent—before installing the new fuse, or the replacement will blow immediately.

For gas dryers, ensure the gas supply valve is open by checking that the handle is parallel to the gas pipe, and observe whether the igniter glows during a heating cycle. If the igniter doesn’t glow, or glows but no flame appears, you need professional diagnosis of the ignition system. If the problem persists after these steps or involves gas components, call a licensed appliance repair technician to diagnose component failures like heating elements, gas valve coils, or control boards.

What causes a clothes dryer to not heat up?

Dryer heating failures stem from interconnected systems where one problem often causes another. Restricted airflow from accumulated lint creates the most problems: as hot, moist air can’t exhaust properly, internal temperatures rise beyond safe limits, triggering the thermal fuse to blow and cutting power to the heating circuit. Even after cleaning the vent, the blown fuse must be replaced before heat will be restored—illustrating how one issue creates a secondary failure.

Electrical problems prevent heat generation in electric models. Partial circuit breaker trips deliver insufficient voltage, failed heating elements create open circuits that block current flow, and deteriorated wiring connections create high-resistance points that prevent proper heating element operation. Each represents a different electrical failure mode, but all result in the same symptom: no heat.

Gas dryers lose heating capability through multiple pathways. Igniters that fail to glow hot enough can’t open the gas valve, faulty gas valve solenoid coils prevent gas flow even when the igniter works properly, and dirty flame sensors cause the control system to shut off gas immediately after ignition as a safety measure. Age-related component wear, improper installation such as wrong voltage supply or closed gas valves, poor maintenance practices, and external factors like building power fluctuations or gas pressure variations all contribute to heating failures.

Most dryer heating problems involve multiple contributing factors rather than a single cause. For example, infrequent vent cleaning leads to lint buildup, which causes overheating, which blows the thermal fuse, which prevents all heating even after the vent is finally cleaned. Understanding these interconnections helps you address root causes rather than just symptoms.

When dryer is not heating up, what should I check first?

Begin your diagnosis with zero-cost checks that require no tools or technical knowledge. These simple inspections solve approximately 50% of dryer heating problems and take less than 15 minutes total.

First, verify your dryer settings. Ensure you haven’t accidentally selected “Air Fluff,” “No Heat,” or another non-heating cycle. Check that the timer hasn’t been bumped to an extremely short duration that ends before clothes dry. This seems obvious, but user error accounts for about 5% of heating complaints.

Second, clean your lint screen thoroughly by removing it and washing with dish soap and hot water. The water test—running water through the mesh—reveals invisible fabric softener buildup that drastically reduces airflow even when the screen looks clean. This blockage causes overheating that triggers safety shutoffs.

Third, inspect the dryer vent system. Disconnect the vent hose at the back of the dryer and look for lint accumulation or kinks restricting airflow. Check that the exterior vent cap opens freely when the dryer runs. In San Francisco apartments, vent systems often run through walls and floors, making professional vent cleaning necessary when blockages occur beyond your reach.

Fourth, for electric dryers, check both circuit breakers at your electrical panel. Both must be fully “on” to deliver the required 240 volts. If one has tripped to the middle position, switch it completely “off” then back “on” to properly reset. For gas dryers, verify the gas supply valve is open by checking that the handle is parallel to the pipe rather than perpendicular.

Only after these basic checks should you consider testing components with tools or calling professional help. Starting with simple solutions saves time, money, and unnecessary component replacement.

How to fix dryer not heating up if it’s still running?

A dryer that runs but doesn’t heat indicates the motor and basic controls are receiving power, which narrows the diagnostic focus to the heating circuit specifically. This is actually helpful information—it eliminates many potential problems.

For electric dryers, this symptom strongly suggests a partial power issue. Your dryer’s motor runs on 120 volts while the heating element requires 240 volts. If one of the two circuit breakers has tripped, the dryer gets 120 volts—enough for the motor, timer, and lights, but insufficient for the heating element. Check your electrical panel and verify both dryer circuit breakers are fully engaged. Reset any tripped breakers by switching completely to “off” then back to “on.”

If power supply is confirmed good, test the thermal fuse—the most common failed component when a dryer runs but doesn’t heat. This safety device blows during overheating incidents, creating a permanent open circuit in the heating system. Use a multimeter to test continuity; a blown fuse shows infinite resistance and must be replaced. Crucially, identify why the dryer overheated (usually clogged vent) and fix that issue before installing the replacement fuse.

For gas dryers that run but don’t heat, observe the ignition sequence. If the igniter glows bright orange but no flame appears, the gas valve coils have likely failed and need professional replacement. If the igniter doesn’t glow at all, test the thermal fuse first (gas dryers have them too), then have a technician diagnose the igniter, flame sensor, or control board.

The running-but-not-heating symptom indicates power is reaching the dryer, so focus your troubleshooting on the heating circuit components: thermal fuse, heating element or igniter, thermostats, and control board outputs to the heating system.

What to do if your dryer is not heating up?

Begin with immediate safety checks, then proceed through systematic diagnosis, and finally decide between DIY repair and professional service based on your findings.

Immediate Actions: Stop using the dryer immediately. Operating a malfunctioning dryer wastes energy, potentially damages clothes from over-tumbling, and in some failure modes, poses fire risks. If you smell burning, see smoke, or notice unusual sounds, unplug the dryer immediately and don’t attempt to use it until professionally inspected.

Initial Diagnosis (15-30 minutes): Perform the simple checks outlined earlier: settings verification, lint screen cleaning, vent inspection, and power supply confirmation. These no-cost steps resolve about half of all heating complaints. Document what you find—this information helps if you need to call a professional.

Decision Point: If simple checks don’t restore heat, you must decide between DIY component testing and professional service. Consider:

Choose DIY if:

- You’re comfortable using a multimeter

- You have basic hand tools

- Your dryer is electric (safer than gas for DIY)

- The symptom suggests a common failure (thermal fuse, heating element)

- You have time to order parts and complete repair

Call a Professional if:

- You have a gas dryer with ignition problems

- You’re uncomfortable with 240V electrical work

- Multiple components seem to have failed

- You lack tools or technical confidence

- Time constraints make DIY impractical

- Your dryer is under warranty (DIY voids coverage)

Taking Action: For DIY repair, order the correct parts using your dryer’s model number (found on a sticker inside the door frame). Follow manufacturer service manuals or detailed online tutorials specific to your model. Test thoroughly after repair before loading clothes.